Guaranteeing quality for us at Bestsea means more than checking appearance, weight and dimension after production. Quality for us starts right at the heart of the company.

There are various type recycle rubber source – Tire , V-Belt, Conveyor Belt, Sealing Ring, Shoe Sole, Rubber Mats and more than hundreds fields. All of them called recycle rubber but has many difference in polymer content , Strength, hardness , density and more performance. Although them could be covered by yellow rubber and hide inside of Speed Hump, but them would be broken easier in a shorter time.

That was why that we have to a lot inspection before production. Normally we spent a lot time to inspect imported Recycle Rubber to make sure the materials are conform to our quality standard.

1. Determination Hardness [ 80 – 85 Shore A Degree]

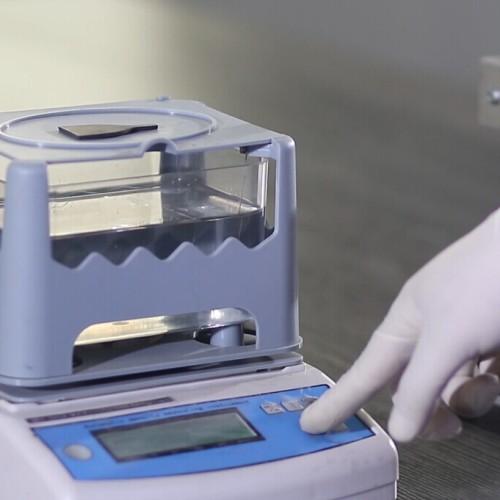

2. Determination Density [In most cases, Less Density Rubber Quality has higher polymer content and better quality].

3. Determination of Ash [ Less Than 5% ]

4. Measurement of vulcanization Characteristics With Rotorless Curemeter

5. Determination of Solventextract

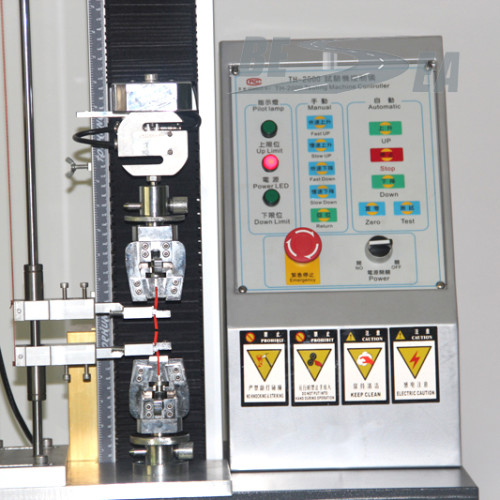

6. Determination of Tensile Stress-Strian Properties

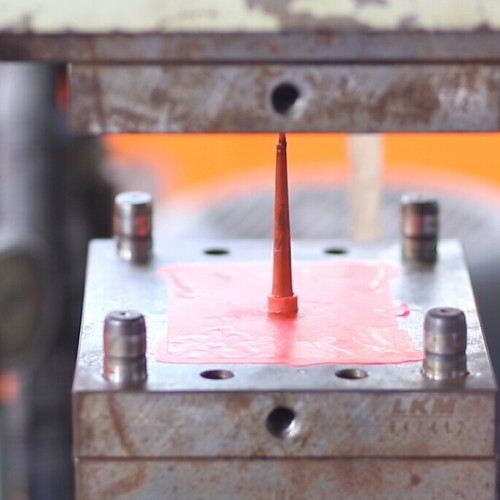

During production, Not only QC inspect, but also our sale departments will go to workshop for inspecting personally as sales known the customer’s requirements most completely.

1. Inspect Appearance.

2. Measure the Dimensions

3. Weighting

4. Assembly Test

Further more, It was most important to test the products in Simulate real environment for checking if them could meet expectation or standard. We often tested the products by heavy container trucks for checking bear capacity, Ice Box for Cold-Resistant, Aging testing for ageing-resistant performance, Heavy Pressing Testing…..

We carefully analyzes every step to ensure that our customers always to receive the best quality products. At Bestsea , quality is our number one commitment.